eSubsea AS is a niche company that provides advanced subsea engineering services and perform mechanical, structural analysis and design, piping analysis and design and finite element analysis and calculations. In addition, we provide a range of subsea products and innovative foundation, anchoring and mooring solutions for offshore wind through Offshore Wind Design AS.

Fast Track Subsea Engineering and Design

We specialise in innovative problem solving and fast track engineering, procurement and construction (EPC) of structures, delivery of subsea products and ad hoc offshore and engineering services, design or verification according to requirements from clients and subsea oil and gas industry codes, recommendations and standards.

The subsea engineering, design and analysis eSubsea can do is listed below:

- Design load estimation

- Lifting sets design

- Padeye and lift point

- Lifting frame/spreader frame design or verification

- Offshore basket design or verification

- Handling and transportation skid design and verification

- Suction anchor engineering

- Suction anchor vent hatch

- Subsea Connection Systems

- Clamp Connectors

- Pipeline Repair Clamps

- ROV Handles

- ROV Tooling

- ROV Buckets and Protection Covers

- Clump Weights

- Load testing procedures or verification of lifting points

- Design and verification of subsea equipment for testing

- Weld stress and weld design

- Bolt and bolt group design

- Piping analysis

- Rigid Jumper Spools or Tie-In Spools

- Flow Induced Vibrations (FIV)

- Corrosion protection

- Finite element analysis (FEA)

- Solidworks Simulation Studies based on CAD models

- Buckling analysis with FEA

- Fatigue analysis and verification

- Dropped object and fishing gear analysis

- Wellhead systems analysis

- Drilling, stabbing and well growth analysis

- Wellhead fatigue analysis, design and evaluations

- Wellhead Load Relief System Calculations and Analysis

- Steel and Aluminium frame design and code checks

- Other structural capacity and integrity analysis and verification

- Mechanical engineering and calculations

- Damage assessment, evaluate remaining structural capacity

- Subsea life time extension studies and evaluations

- Review and comments to subsea structures design documentation

- Consultancy and discussion on any subsea engineering issue

- Research, study, mechanical engineering support and development support

- Assistance with underwater and upstream patent applications

- Online learning and training for engineering graduates with degree in engineering

- Contact us for other fast track engineering assignments

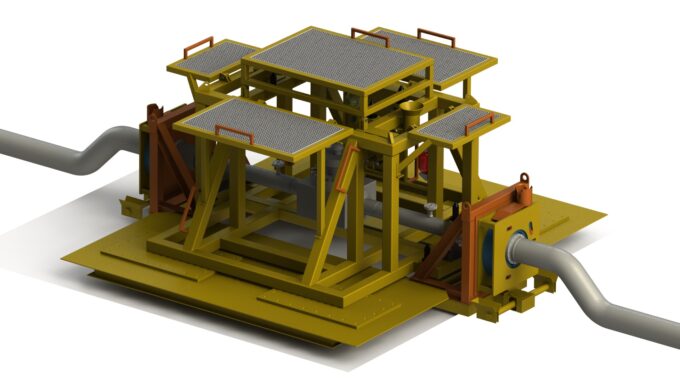

Subsea Products

eSubsea deliver high quality subsea products and production equipment worldwide directly or through our partners. The products are standardized, or custom designed and engineered to suit the customers’ requirements.

eSubsea and our partners can deliver subsea products, concept studies, engineering and design services and offshore and underwater hardware to the North Sea, Gulf of Mexico, Canada, Australia, West of Africa, Brazil and Russia

Subsea Codes and Standards

eSubsea can guide you through the jungle of offshore and subsea codes, standards and recommendations and help decide which codes, standards and recommendation are applicable for your assignment. The lifting analysis, design and verification of lifting equipment can be done according to any recognised offshore oil and gas industry standards such as DNVGL-ST-E273, NORSOK R-002, DNVGL-ST-0378 (DNV 2.22) etc.

Structural and Piping Analyses

eSubsea utilise the latest of powerful structural, mechanical and piping analysis software as SAP2000, TRIFLEX and Solidworks Simulation to effectively analyse, verify or design any deep water offshore or subsea structure, foundation structures or piping, equipment, parts or component.

Structural analysis code checks are normally according to NORSOK N-004 or Eurocode 3, but most international design codes can also be used. Dropped object protection, fishing gear analysis, wellhead fatigue and design of subsea wellhead system will be according to NORSOK U-001. Piping analyses, advanced pipe stress analysis and code checks are generally according to ASME b31-3 and ASME B31-8.

If the scope of work of your subsea engineering task is more than what can reasonably be executed within a few days, eSubsea will revert with a proposed fast track project schedule, normally with results delivery within only a few weeks.

Engineering and Design of Subsea Structures

If urgent fast track engineering and design is not required, more in-depth design and analysis projects can be executed on a more normal time scale.

In addition to the structural, piping and mechanical engineering tasks mentioned above, eSubsea can together with our partners do:

- Advanced lifting and installation analysis of offshore structures

- Design of connection and tie-in systems

- Design of manifold piping flex loops and flow assurance

- Structural analysis of subsea protection structures

- Structural analyses of underwater foundation structures

- Template and Manifolds

- Mudmats and Clump Weights

- Riser Bases

- PLEM, PLET, FLET, Pipeline End Modules

- SSIV, Subsea Safety Isolation Valve Modules

- HDU, Hydraulic Distribution Units

- UTA, Umbilical Termination Units

- SDU, Subsea Distribution Units

- EDU, EDA, Electrical Distribution Units or Assemblies

- HIPPS, High Integrity Pressure Protection System

- PLR, Pig launchers and receivers, Pig Traps

- 3D modelling and CAD drawings

- Graduate assistance and applied mathematics

- Geotechnical and foundation calculations

Offshore Wind Foundations

eSubsea is also an engineering and design company with the experience and technical knowledge and understanding to get involved in the upcoming green transition from the upstream oil and gas industry into the emerging renewable Offshore Wind Industry with special focus on the design of cost-effective foundation structures for both bottom fixed and floating offshore wind farms.

We have recently formed a new company, Offshore Wind Design AS, that shall focus on offshore wind foundations and innovative mooring solutions.

The bottom fixed offshore wind foundations design include gravity based, mono-piles and jacket types. The floating wind foundations are TLPs, semi-submersible and SPAR types. Both the fixed and floating foundations use suction anchors as foundations and offshore wind mooring anchoring.

With extensive experience from the advanced technology and innovation driven subsea technologies, we knows what it takes to design, engineer, fabricate, test and safely install complex underwater foundation structures.

Subsea Storage of Hydrogen

Storage of Hydrogen (H2) and Ammonia (NH3) can be safely done underwater using pressure containing or ambient tanks, advanced materials technology and field proven engineering principles from the subsea oil and gas industry. The advanced subsea technology and extensive experience developed over the last 25 years can now be “recycled” and applied for the new renewable sources of energy.