eSubsea AS is the owner of a new company, Offshore Wind Design AS, that are developing and patenting several innovative floating offshore wind mooring system solutions for the renewable energy industry. The inventions can reduce cost directly by up to 30% and increase the load capacity with up to 300%. Lean more at Offshore Wind Design – Foundation, Anchoring and Floating Offshore Wind Mooring Solutions.

eSubsea perform engineering, analysis, optimization and design of offshore wind foundations, anchoring and mooring systems.

We are currently working on geotechnical optimisation on several offshore wind projects such as Utsira Nord, Sørlige Nordsjø II, Trollvind and ScotWind. IN addition, we are also working on generic fishing friendly wind farms design.

The mooring systems for offshore and subsea floating offshore wind foundations are normally either one of three systems or a combination of the following anchoring systems:

- Vertical tension leg mooring

- Taut angled mooring lines

- Slack Catenary mooring lines

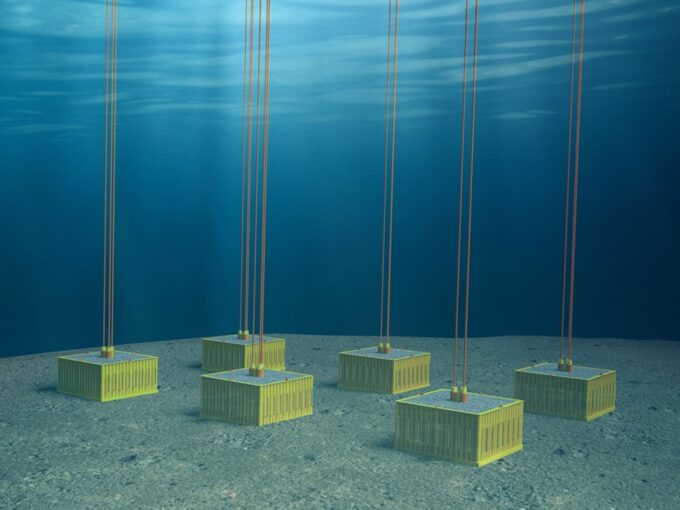

Vertical Tension Leg Offshore Wind Mooring

The vertical tension leg mooring system is station keeping the floating offshore wind foundation by means of heavy steel rods or wires anchored on the seabed. The braces must always be stretched and pre-tensioned as the buoyancy is greater than the weight of the structures.

This is achieved by the foundation being pulled down below its normal water line. Thus, the vertical movement of the wind foundation due to waves will also be limited to the elastic elongation of the braces. Tension leg wind floating foundations are well suited for mooring at large sea depths. The foundation structures or clump weights need to take large vertical loads due to the nature of the vertical tension leg moorings.

Taut Angle Mooring Lines

The lightweight vertical taut leg mooring line system consist of anchor lines that are subjected to pre-tension such that they are taut and are in principle utilising the tent effect. The lines are radiating outwards from the floater.

Compared to a tension leg anchoring system, the taut anchoring is angled from the seabed to the offshore wind foundation and will take loads both in vertical and horizontal direction. The mooring system is suitable for deep water offshore wind as the angled lines gives more load sharing between the mooring lines.

Catenary Offshore Wind Mooring System

The most used subsea wind mooring system in normal water depths is the catenary mooring system. Most drilling rigs and semi-submersible based offshore floating wind foundation use this system. The anchoring system is horizontal at the seabed and the forces to provide station keeping is generated by lifting of the chain off the seabed. The chains or heavy steel rope need to very long compared with the water depth and hence fiber ropes are an alternative for parts of the catenary mooring for floating offshore wind foundations. The seabed foundation for the catenary mooring systems can normally not taken any vertical loading.

The station keeping system use stud less or studded chains, polyester based synthetic or lighter steel wire ropes for tether line materials. The mooring lines terminate at the seabed with the subsea anchors. These can be suction anchors, plate anchor, fluke anchor or deep piles.

Mooring Design Codes and Loads

The tether line design is according to the mooring line design code DNVGL-ST-0119 Floating wind turbine structures. The calculation of structural forces into the offshore wind anchoring and mooring systems are calculated either by using dynamic analysis or a quasi-static method. The different loads from the wind turbine, wind, wave and current is combined into the appropriate load combinations. The subsea mooring lines will be designed for all load factors and relevant limit states as the Ultimate Limit State (ULS) and Accidental Limit State (ALS) and Fatigue Limit State (FLS), when subjected to the all relevant environmental and wind turbine forces.