Floating offshore wind foundations has an advantage over onshore wind turbines because the sea has more wind and more stable wind resources. The sea also has better space for large wind parks.Wind quality usually increases with distance from land, both in terms of wind strength and turbulence. In order to exploit these wind conditions, work is underway to develop new technology that will open areas further offshore for wind power generation.

eSubsea AS is the owner of a new company, Offshore Wind Design AS, that are developing and patenting several innovative mooring solutions for the Offshore Wind Industry. The inventions can reduce cost directly by up to 30% and increase the load capacity with up to 300%. Lean more at Offshore Wind Design – Foundation, Anchoring and Mooring Solutions for Offshore Wind.

A More Sustainable Future

eSubsea strives to participate in the development of offshore wind turbine and in particular engineering and design of substructures. The engineering and design follow the principles, technical requirements and guidance given in DNV-ST-0119 Floating Wind Turbine Structures.

The challenges are that there are greater investment costs associated with offshore development. It is also more expensive to maintain and operate offshore wind farms compared to onshore parks. There are currently no commercial floating offshore foundations built on deeper water than 50 meters. The reason for this is the high costs involved in the development of deeper water. There are therefore great opportunities for improvement and industrialization in this field – and a great need for research and development. eSubsea aim to participate in this development.

Floating Foundations for Deeper Waters

For floating offshore wind mooring, substructures or foundations, there are 3 main types of foundation concepts and mooring systems used. These concepts are taken from the offshore drilling rig designs and are:

- Tension Leg Platform (TLP)

- Semisubmersible (Semi-sub)

- SPAR

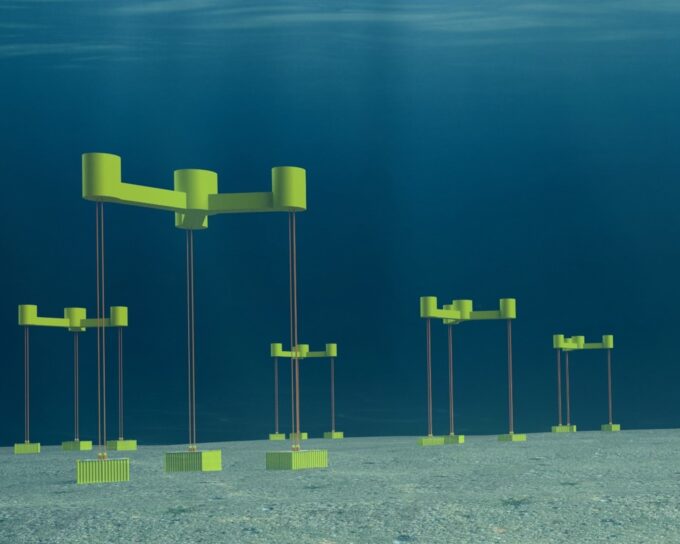

Tension Leg Wind Foundation

A Tension leg platform (TLP), is a floating offshore wind foundation that is kept at rest by means of heavy steel rods anchored on the seabed using suction anchors or suction caissons. The legs must always be stretched, this is achieved by the foundation being tensioned down below its normal water line. Thus, the vertical movement of the platform due to waves will also be limited to the elastic elongation of the braces. TLP foundations are well suited for production at large sea depths. Offshore Wind Design design offshore wind mooring solutions that are optimized for TLP concepts.

Semi-sub Wind Substructure

A semi-submersible foundation or a semi-sub foundation is a type of floating wind foundation that is partly submerged to provide station keeping and stability. It typically comprises a submerged hull typically pontoon-type columns joint together with the foundation by large tubulars. The benefits with the semi-sub is to avoid large wave loads by having the smaller tubulars in the splash zone. The mooring solution is normally clump weight foundations for hard soil conditions and suction anchor foundations for softer soil.

SPAR Floating Offshore Wind Foundation

A SPAR is a cylinder that floats vertically in the water, often with ballast tanks in parts of the cylinder volume. Such wind foundation types may also be constructed of steel, concrete or a combination thereof.

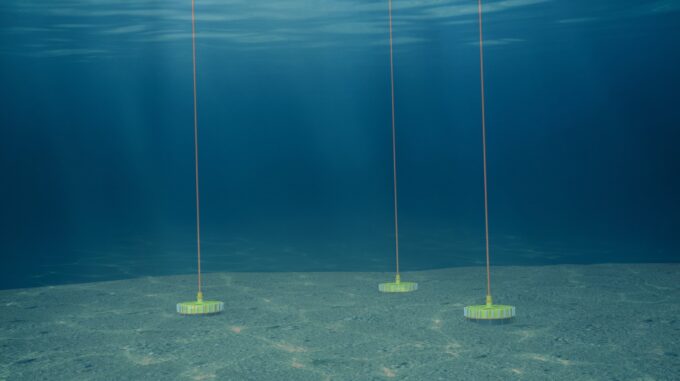

Suction Anchors for Floating Offshore Wind Foundations

eSubsea provides structural analysis and design of suction anchors or suction caissons for offshore wind foundations. The offshore wind suction anchor will be design for all design loads such as dynamic loads from waves and current and wind turbine generated loads, installation and removal loads from suction/over-pressure and levelling. The anchor foundations or mooring of suction anchors, fluke anchors, pile, gravity and plate anchors also follow DNV-ST-0119 Floating Wind Turbine Structures.

We are currently working on geotechnical optimisation on several offshore wind projects such as Utsira Nord and Sørlige Nordsjø II.

Offshore Wind Concept Development and Technology Qualification