eSubsea provide fatigue analysis of any structural components or parts, including bolts and welds, subjected to cyclic loading. We also have extensive experience with wellhead fatigue design analysis and wellhead load relief evaluations. We also do piping analysis where vibrations and fatigue damage may be an issue due to Flow Induced Vibrations (FIV).

Analysis using Finite Element Method

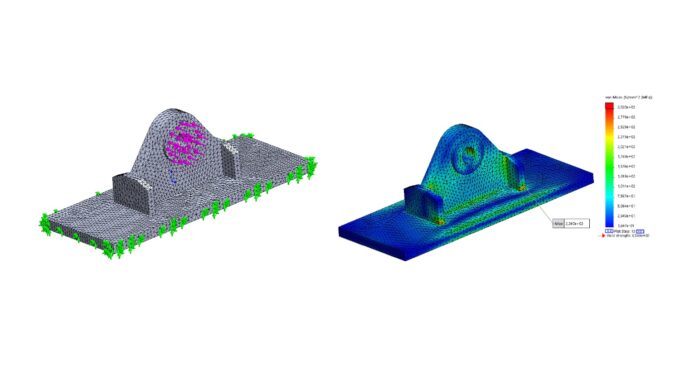

The fatigue analysis will be done using finite element analysis of the component. The cyclic loads are applied to the FEA model, the load paths established and hot spot stresses and stress concentration factors identified.

The fatigue limit state (FLS) is the stress strain when the number of cycles goes to infinity. There no fatigue cracks or crack growth in this limit state. In theory, a subsea construction is safe from fatigue failure when the number pairs of stress and cycles at any location fall below the S – N curve. However, there is a large spread in the fatigue sample test numbers, and the resistance to fatigue also varies considerably from place to place in a real construction due to the hot spot stresses.

eSubsea can use finite element analysis to identify the hot spot stresses and plastic deformation in any structure or construction.

SN Curves and Miner-Palmgren

Therefore, the calculation regulations use S – N construction curves, which, based on a statistical evaluation of the test results, assume a probability of survival of 97–99%, depending on the damaging effects of fractures.

Using the number of cycles to failure and S/N curves from DNVGL-RP-C203 Fatigue Design of Offshore Steel Structures the fatigue damage or fatigue total life can be calculated using rainflow cycle coating and Miner-Palmgren cumulative damage theory.

Fatigue is a very central theme in offshore wind, both for bottom fixed and floating foundations and for offshore wind mooring systems. Cyclic and dynamic loads from the generator, wind, waves and current must all be combined and all parts of the substructures checked for fatigue and eigen frequencies and resonance considered.

eSubsea also do third party fatigue design and verification checks.