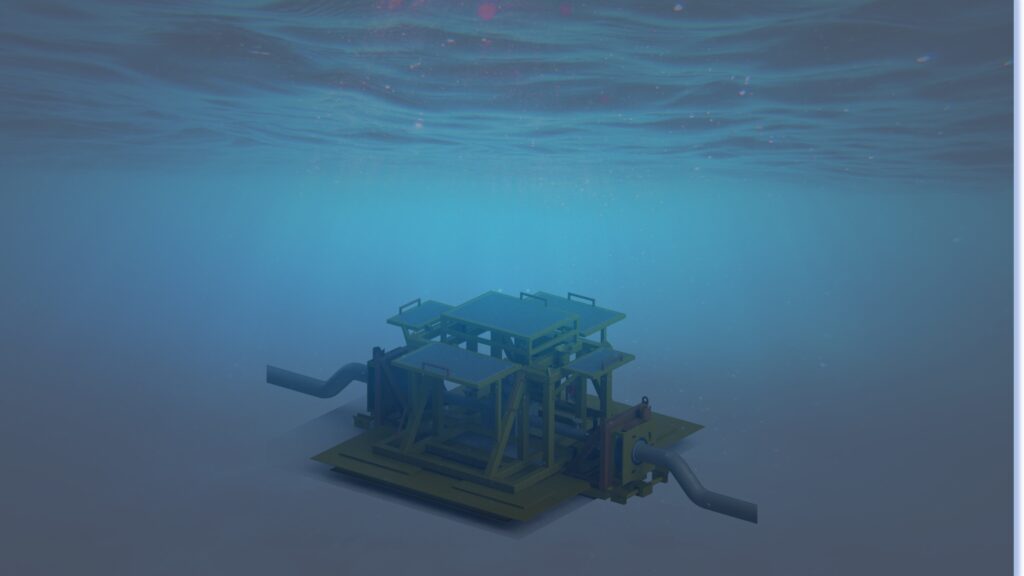

The subsea foundation structures and protection structures are an important part of the subsea production system. The purpose is to permanently secure the subsea equipment to the seabed and provide protection against operational and accidental loads through the design life.

Subsea Foundations

The purpose of the subsea foundation structures is to secure the subsea structures and modules to the seabed. The foundations can be installed separately, integrated with the protection structure or fully integrated with the subsea manifold module.

eSubsea perform fast track engineering, analysis and design of all types of subsea structures and foundations.

For soft seabed conditions (clay/sand) the foundation will penetrate with suction anchors /skirts, most often by the aid of a ROV assisted suction system. For bearing of the subsea modules self-weight and to withstand installation and operational loads, the mud line of the foundation has mudmat areas that rest on the seabed.

The foundation will need to be designed for load cases such as fabrication, load-out, transportation, installation, piling, earthquake, pipeline and spool loads, fishing loads, dropped objects, drilling loads (if drilling template).

Types of Seabed Foundations

The foundation concept selection and detail design of these systems are dependent on local seabed conditions, size and weight of the component (manifold, FLET, PLET, PLEM, In-line sleds, HIPPS, SSIV, EDU, UTA, SDU, Xmas tree and spools). In addition, technical requirement from codes and standards and the Field Operators own preferences and requirements are design drivers.

The most common types of foundations are suction anchors (either single or in clusters normally a 4-pod), skirted foundations (with or without piling) and gravity-based foundation structures.

Integrated Protection Structures

The protective structures can be categorized as either free standing (where there is no contact between the subsea module and the protection structure), integrated with a subsea manifold or integrated with a drilling template.

A critical selection criterion is the requirement for a subsea protection structure. Most structures will have requirement for dropped object protection. Hence, a roof panel or hatch is required above the subsea equipment. Equipment can be protected locally by structural steel frames or GRP covers. If the equipment itself has sufficient structural strength to withstand the dropped object requirement, not additional protection is needed.

Weight limitations may be a part of the evaluation as installation vessels may already been selected with a certain crane capacity. It the total weight is too high; a separate protection structure should be considered. Also, the weight of the structures will require the structural frame to be designed to certain dimensions.

The in-place load cases will give the required mudmat area and skirt/anchor dimension.

The requirement for fishing protection will give the design of the outer perimeter of the structure. The structure may be open, partly closed of fully closed based on the local requirement or the Field Operators preferences.

As an example, failure to comply with overtrawling requirements will result in an additional snag load to be introduced, which in turn will require large structure or piling. Selecting the optimum foundation and protection concept is the key to a cost-effective subsea project.

Foundation Structures

eSubsea do fast track engineering, analysis and design of the following types of subsea foundation structures which will be described in more detail below:

- Skirted with mudmats

- Piled foundations

- Gravity based

- Suction anchor

- Free standing

- Cluster manifold integrated

- Drilling template integrated

- Clump weights

Skirted Foundations

Skirted foundations can be used were the soil is firm enough (clay) to provide sideways resistance by using skirts that penetrate into the seabed (normally 2 m depth). Suction may not be required as the structure self-penetrate to required depth by self-weight and rest on the mudmat areas. If suction is required mudmat hatched with suction holes can be added and applying under-pressure in the mudmat chambers lowers the structure to target depth. Skirted foundations can be used for most types of subsea modules as drilling templates, cluster manifold and PLEMs.

Piled Foundations

For harder and often sandy soil conditions, where suction anchors will not penetrate to required depth, piling can be used to secure the foundation to the seabed. The four corners of the foundation will be pile sleeves. The structure will be installed, and a hammer drives the piles, often 20-30 meters deep. Pile driving will be an additional load case for this option and sufficient mudmat area should be ensured.

Gravity based foundation

For hard and very hard seabed, a gravity-based foundation can be used. The gravity-based foundation is supported by mudmat areas and is horizontally supported by the friction between the seabed and the structure. The friction is a result of the seabed/steel friction and can be increase by adding small skirts to the perimeter of the mudmat areas. If the in-place weight (submerged) is lower than required, ballast can be added.

Suction Anchor Foundation Structures

Suction anchors or suction caissons are used for soft/ultra-soft seabed. They are quick to install and cost effective. The length and diameter of the anchor/pile is determined by the required bearing capacity or geotechnical capacity (weight of the subsea module and loads) in combination with the local soil conditions. It is required to have information about soil parameters to suction pile length for optimum design.

The anchors self-penetrate to a depth and suction is applied to penetrate to target depth. Suction is applied to a suction hatch on the top of the anchor compartment. For deep water and very soft soil conditions were fishing protection is not required, single suction anchors are used with a central guide mast that the subsea module will land out on. For heavy drilling templates with integrated protection and free-standing protection structure, four suction anchors are joined together to form the foundation structure.

Suction anchors are also commonly used as foundation for floating offshore wind structures.

Free Standing Foundations

The free-standing protection structure is installed above the subsea module. It has is its own foundation, normally suction anchors on each of the four off corners. Large tubular corner members support the top roof. The sides may be open or closed by including hatched that gives additional protection for protruding equipment, such as pipe spool connections. The top of the structure has hatches that may be opened and closed to remove or install replaceable components. A clearance between the top of the module and the protection structure provide easy access for ROV without opening hatches

Cluster Manifold Integrated

Combining the protection structure frame with the foundation structure frame can protect the subsea manifolds. The manifold module can either be integrated or be separately retrieval, which means that the manifold module can be retrieved to surface without having to retrieve the foundation/protection structure. Also, the four corners of the structure can have pile sleeves such that the structure can be piled to the seabed.

Drilling Template Foundation Structures

Drilling templates often have integrated foundation and protection structure. The main driver for this is the total weight saving compared to having the separate. The heavy weight of the drilling template required large tubular structural members that are also required for fishing protection. The structure can be open, partly or fully closed by hatches. For integrated structures, special attention will be on ROV access.

Clump Weights

The clump weight foundation is a version of the gravity-based foundation for hard and very hard seabed. The clump weight also gets its horizontal load capacity from the friction between the seabed and the structure.

Applicable Codes and standards for design of subsea foundation structures.

Subsea Foundations Concept Study

eSubsea with its engineering and geotechnical partners can carry out fast track concept and feasibility studies which include concept evaluation, preliminary foundation sizing based on input loads, dropped objects and trawling requirements, penetration resistance, bearing capacity and required suction or weight. The concept study is a cost effective way to quickly establish size, weight, budget cost and delivery schedule for your project.