eSubsea AS is the owner of a new company, Offshore Wind Design AS, that are developing and patenting several innovative mooring solutions for the Offshore Wind Industry. The inventions can reduce cost directly by up to 30% and increase the load capacity with up to 300%. Lean more at Offshore Wind Design – Foundation, Anchoring and Mooring Solutions for Offshore Wind.

eSubsea has the knowledge, experience and expertise to perform all required design and engineering tasks for detail design of the offshore wind turbine foundations.

We are currently working on geotechnical optimisation on several offshore wind projects such as Utsira Nord, Sørlige Nordsjø II and ScotWind. In addition, we are also working on generic projects, such as a fishing friendly wind farm design.

Bottom Fixed Foundations

For bottom fixed offshore wind turbine foundations there are three off main types used:

- Gravity based foundations

- Monopile foundations

- Jacket type foundations (also a tripod is used)

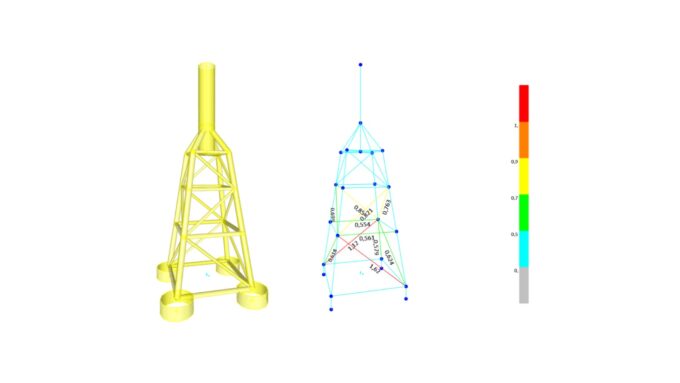

Jacket Wind Foundation

The Jacket type wind turbine foundations is most suitable for deeper waters (50 – 80 meters) and consists typically of the following main subsystems:

- Transition piece

- Work platform and boat landing

- Jacket support structure with J-tubes

- Suction anchors or suction buckets or pile sleeves foundations

Transition Piece

The transition piece transfers the loads and weight of the wind turbine tower and generator to the jacket support structure legs and is the top part of the jacket wind foundation.

The work platform and boat landing area are outside the transition piece and gives access for installation and maintenance of the wind turbine.

The main function of the support structure is to transfer loads from the turbine to the ground, allow access to the turbine for maintenance and control and to support cables down to the seabed.

The jacket structure is fixed to the seabed by suction anchors or traditional pile sleeves. It is believed that suction anchors will be more used in the future and will be used in the design. The suction anchor design is highly dependent on the soil conditions at the site.

Detail Engineering and Design of Fixed Offshore Wind Turbine Foundations

The analysis and design is used with the most advanced structural design and finite element analysis software.

- Design Basis

- Structural Design and Analyses

- Wind and loads from turbine

- Waves and current

- Earthquakes

- Finite Element Analyses

- Fatigue Analyses

- Cathodic Protection Calculations

- Material Selection

- 3D Modelling and Fabrication Drawings

- Interface handling

- Outline Testing Program

- Outline Installation Procedure

We collaborate and interface with your geotechnical adviser or used one of out partners for the geotechnical detail design.

Standards, Guidelines and Recommended Practices

The design will be carried out according to acknowledges and recognized codes and standard in order to have the design and project certified by any certifying Authority. The following standards are used throughout the design among many others:

- DNVGL-ST-0126 Support Structures for Wind Turbines

- DNVGL-ST-0145 Offshore Substations

- DNVGL-ST-0437 Loads and Site Conditions for Wind Turbines

- DNVGL-RP-0005 Fatigue Design of Offshore Steel Structures

- NORSOK N-004 Design of Steel Structures

- DNV-RP-B401 Cathodic Protection

- DNVGL-RP-0416 Cathodic Protection for Wind Turbines

Offshore Wind Foundation Concept Study

eSubsea with its engineering and geotechnical partners can carry out fast track concept and feasibility studies which include concept evaluation, preliminary foundation sizing based on input loads, penetration resistance and required suction or weight, stability, bearing capacity and skirt wall thickness. The concept study is a cost effective way to quickly establish size, weight, budget cost and delivery schedule of the foundation for your offshore wind project.