Subsea connection systems are ROV operated horizontal and vertical tie-in connections used in the subsea oil and gas industry for connecting rigid or flexible flowlines, pipeline and jumpers with subsea piping modules such as wells, manifolds, in-line tees and riser bases.

Subsea Connection Systems

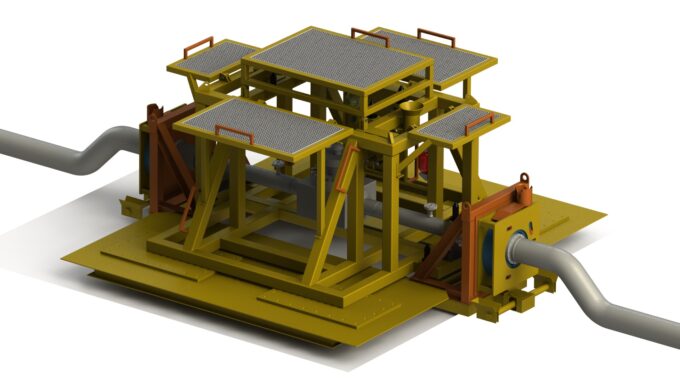

eSubsea provide design, engineering and verification of subsea connection systems including piping analysis. Through our partners, we can deliver cost-efficient field proven and reliable diver and driverless subsea connection systems and hydraulic couplers with ROV tooling for oil and gas production and water injection for all water depths including deep and ultra-deep water. Both vertical and horizontal ROV operated connection systems can be provided in nominal sizes from 2 Inch all the way up to 36 inch with high pressure (5,000 psi (345 bar), 10,000 psi (690 bar), 15,000 psi (1,035 bar)) and high temperature capabilities. The diver-less subsea connections system is delivered complete with all required transportation and handling equipment, seals and gaskets, ROV Handles, consumables and required subsea tooling.

Included in the line of connection products are also hydraulic couplers used for scale squeeze and chemical injection.

Subsea Clamp Connector

The large and small-bore connectors are basically subsea clamp connectors with metal to metal sealing. The clamp are equipped with a single drive screw and ROV bucket according to relevant codes and standards and have backseat testing capabilities.

The subsea flowline connection systems include misalignment capabilities which is essential for reduction of residual pipe stress and to minimize the risk of hydrogen induced stress cracking (HISC) as per DNVGL-RP-F112. The misalignment tie-in and connection systems are used for tie-in and connection operations of wells, rigid jumper spools, pipelines and flowlines, template and manifolds, riser bases, PLEM/PLET and other pressure containing subsea structures.

The clamp connector system is fully piggable and can be used for pig launchers and receivers. The subsea connection system also includes cathodic protection and thermal insulation.

All welding, coating, parts and components of the clamp connection system is designed and built to the highest quality control standards and with the best materials according to API 6A and API 17D.

Collet Connector

A collet connector is also available and is a high-pressure hydraulic connector which is made up and released by the ROV using hydraulic supply. A field proven 18 3/4 inch wellhead connector is available and field proven. The collet connector is engineered integrated into existing guiding and support structure for any subsea application and is also piggable. The collet connector works using a number of locking segments which constitute the locking mechanism between the hubs with correct pre-tension.

The segments are operated to lock unlock position by a locking ring operated by a set of hydraulic cylinders. The seal is suspended in a seal retainer bolted to the connector body. The collet bore configuration can be single or mono-bore and multi-bore. The application can be all types of rigid and flexible flowline and jumper connections, manifold and Xmas trees wing hub connections and umbilical connections.

Subsea Pipeline Repair Clamps

eSubsea and our partners deliver engineering, procurement and construction (EPC) of diverless subsea pipeline repair system for all oil and gas pipeline sizes and types of connections. The permanent structural pipeline repair clamps will effectively encapsulate, seal off the leakage and contain pressure for the remaining design life without need for any maintenance. Pressure monitoring devices using ROV hot stabs to verify clamp sealing may be included in the design.

The pipeline pressure retaining system, which is in particular suitable for deep water application, may also incorporate subsea thermal insulation or a “dog-house” solution. The low weight pipeline repair system will also protect the pipeline from additional loads by properly supporting the pipe or connectors. The subsea clamp leak repair system effectively seals of the pipes.

The pipeline repair clamps can also be used for hot tapping of existing pipelines when including a pipe branch to interface the connection system. Combined with the subsea connection system with misalignment capabilities, this gives a smart and cost-effective hot tap solution. Cathodic protection of the leak clamps and hot tapping clamps using subsea coating, cathodic protection and suitable material selection will also be included in detail design.

Subsea Connection System Tooling

The standard tooling available for the subsea connection systems are: Pipeline repair coating removal tool, Seal replacement tools, Seal cleaning and inspection tool and stroking tools for pull-in and connection. In addition, other types of ROV tooling for intervention and lifting tools can be provided or custom design.

Onshore and Topside Connectors

With minor modifications, the connection system can also be utilised for topside and onshore applications. The misalignment capability will reduce the required tolerances for the piping lengths and effectively remove the stresses from forcing the correct angle on the pipe during connection.